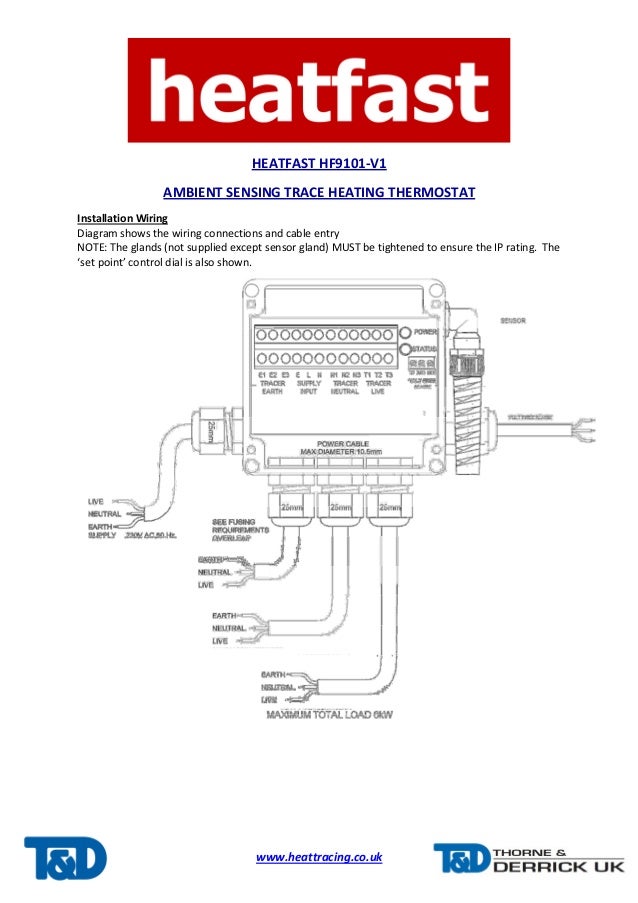

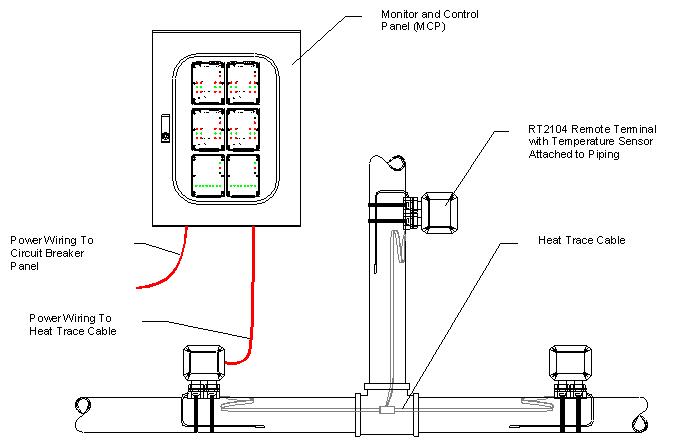

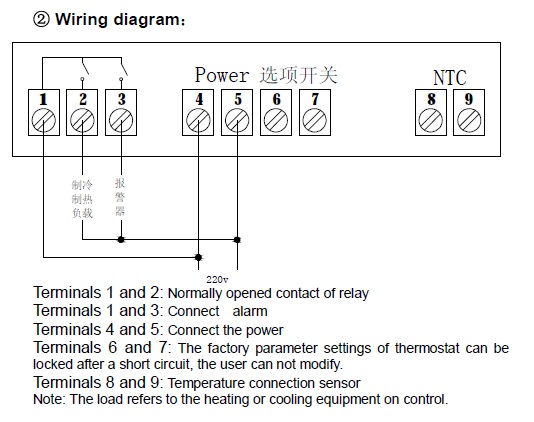

These are a com plete temperature control and system management so lutions for electrical heat trace applications. A wiring diagram is a simplified traditional photographic depiction of an electrical circuit.

Wh7016e Temp Controller Amp Cedaronics Enclosure Heat Trace

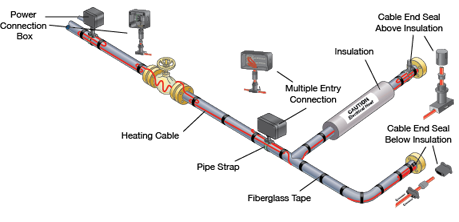

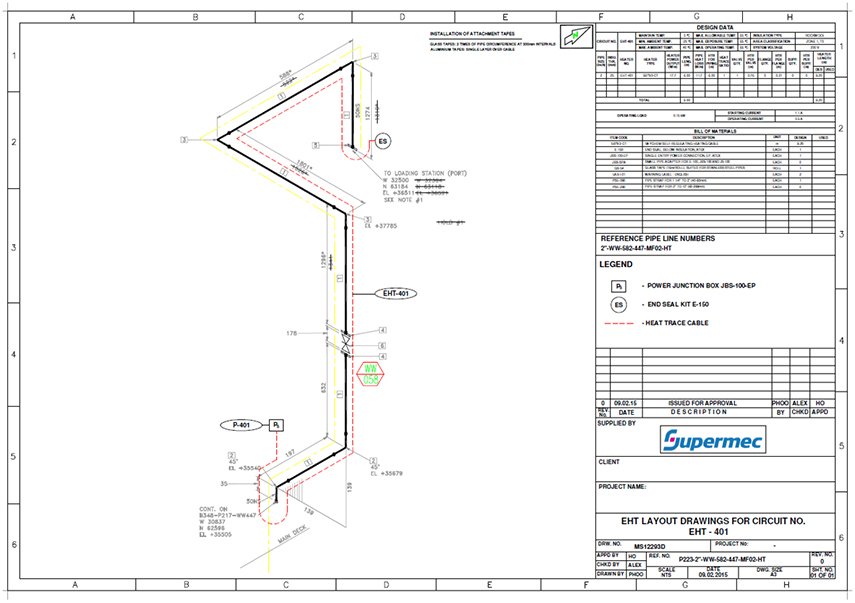

Heat trace wiring diagram. Warranty pentair thermal management standard limited war. The chart below compares heating cable power output with prod uct rating. Xl trace heat tracing systems carry agency approvals for the different applications shown in section 12. Symbols that represent the components inside circuit and lines that represent the connections together. Lay out the trace heater on the pipe at the 4 or 8 oclock position illustration b securing it tightly against the pipe with attachment tape. Wrap bands of tape around the trace heater and pipe at intervals of 12 30 cm or less keeping the trace heater in close contact with the pipe.

A wiring diagram is a simplified standard photographic depiction of an electrical circuit. Electric heat tracing. A wiring diagram is a kind of schematic which uses abstract pictorial symbols to show each of the interconnections of components in a system. Ngutc 2030 and ngutc 2230. The intellitracetm itc fs1 and itc fs2 provides the. The intellitracetm family of heat tracing products continues to expand with its latest single or two circuit controllers the itc fs1 and itc fs2.

Power adjustment factor part no. 208 volts 277 volts 2703 2 75 128 2705 2 86 116. Heat and control products. Assortment of heat trace wiring diagram. Alternate voltages rscc 240 vac self regulatingheating cables can be operated at alternative voltages. Heat trace pipes valves and flanges.

Heat loss calculations and system design. Isometric system diagrams if provided. Heat trace wiring diagram. Heat trace wiring diagram whats wiring diagram. It shows the elements of the circuit as simplified forms as well as the power as well as signal links in between the devices. Wiring diagrams comprise a couple of things.

For detailed information on which approvals are carried for the specific applica tion refer to the pipe freeze protection and flow maintenance design guide h55838. Maintenance of electric heat tracing systems shall conform to all iec requirements for the use of electrical equipment and with the requirements of the relevant heat tracing standard usually either iec 62395 electrical resistance trace heating systems for industrial and commercial applications or iec 60079 30 explosive atmospheres electrical. It reveals the components of the circuit as simplified forms and also the power and signal links in between the devices. Assortment of heat trace wiring diagram.