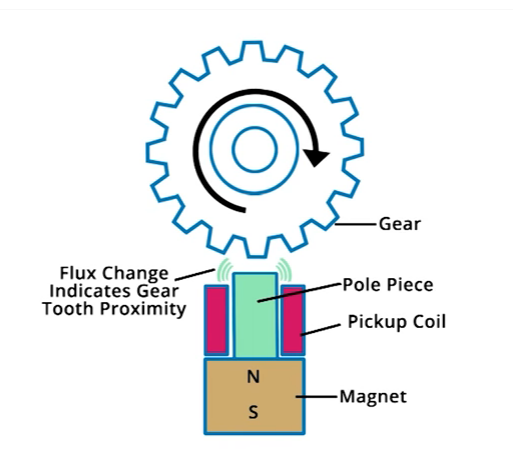

Inductive and hall effect rpm sensors explained. Since he is testing the 2 wire speed sensor while it is out of the vehicle he breaks out the high powered drive device a drill to spin the sensor at the necessary rpms to generate a signal.

Sr20ve Rpm Switch Problem Trinituner Com

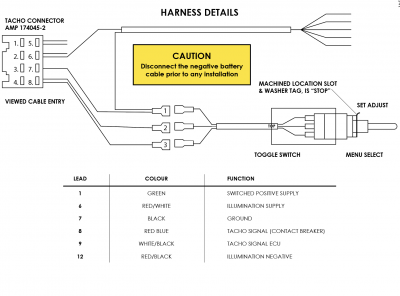

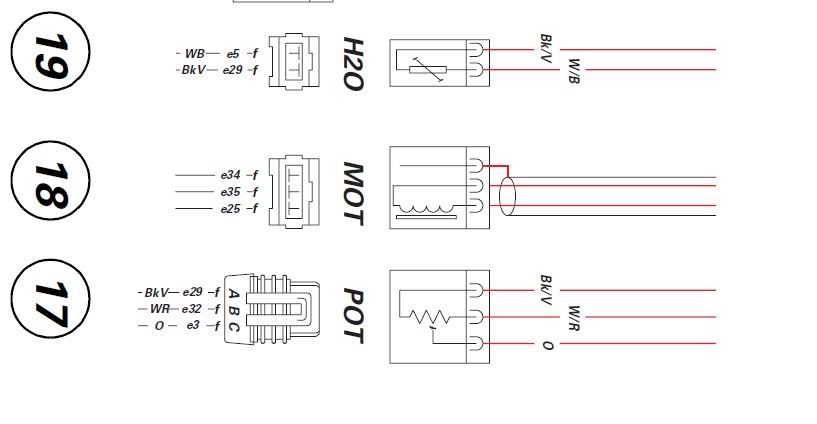

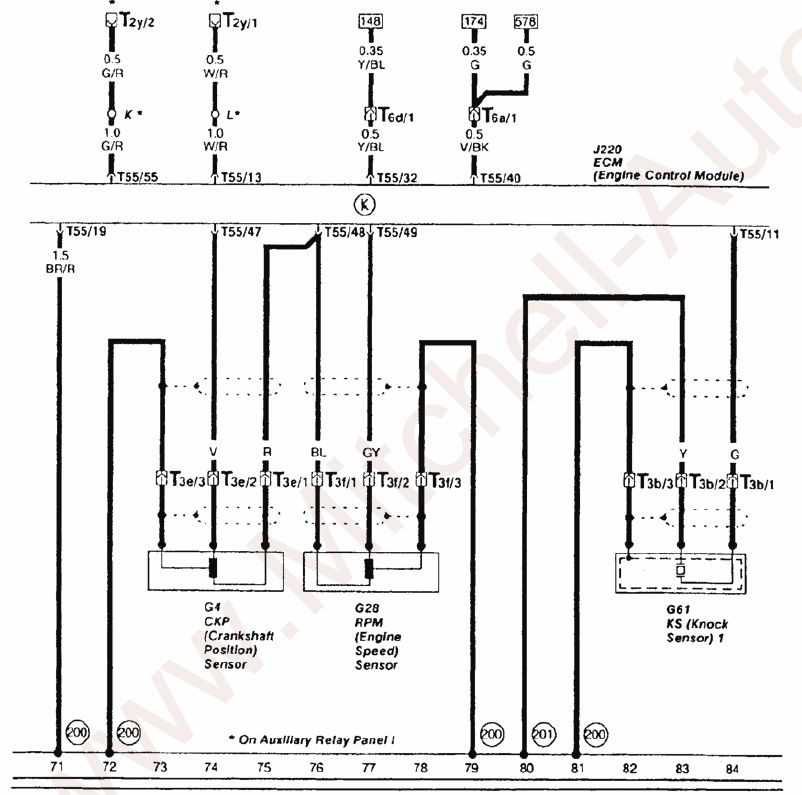

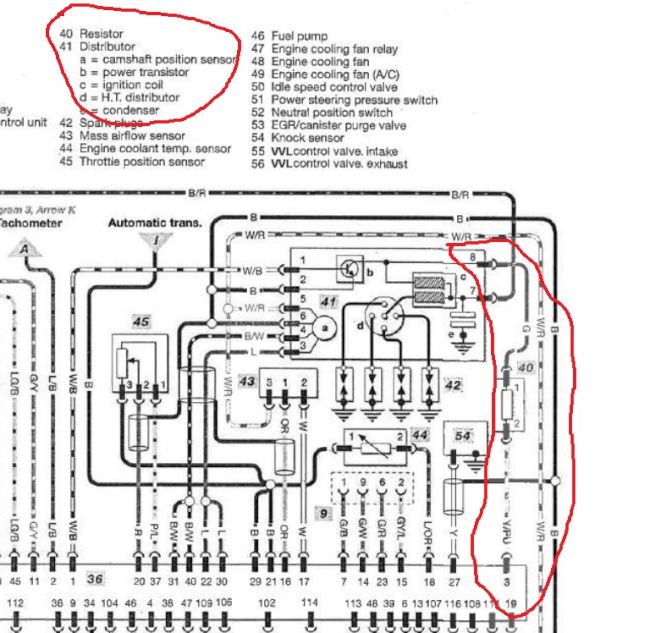

Rpm sensor wiring diagram. The dsl 1 was mounted below the instrument cluster. Refer to the wiring diagrams figure 8 to figure 23 for proper wiring installation. Here is a description of electrical wires on connector. If you are intending on testing the vehicle you will actually have to drive the wheels with the engine to obtain sufficient rpms to generate a signal. Install four screws to. Tachometer signal or coil or tachometer sensor in order to measure engine speed rpm.

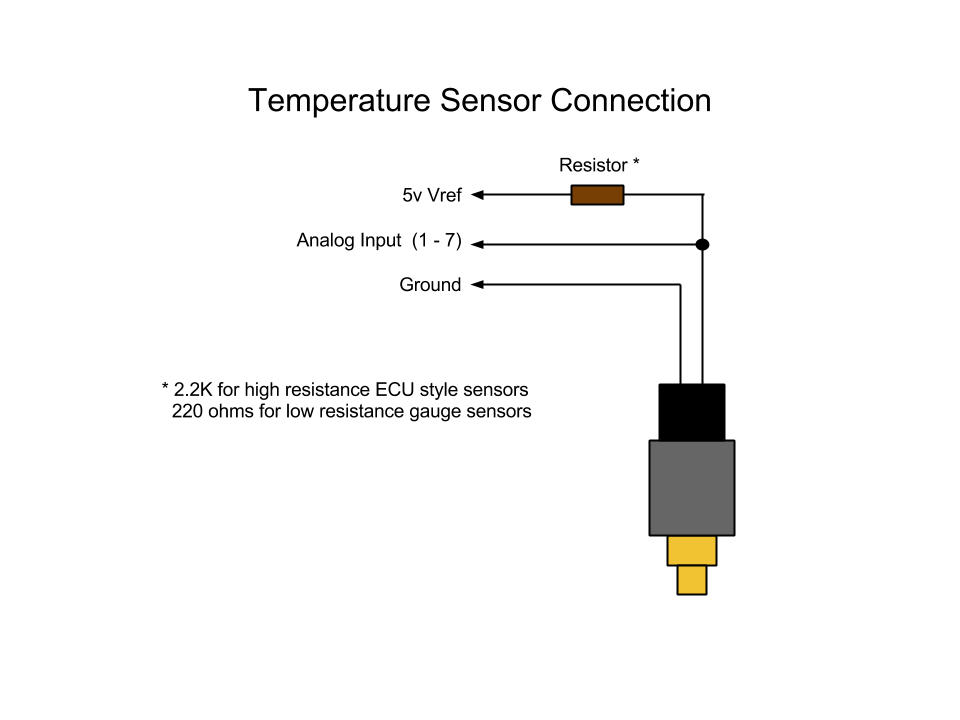

Cable dcf flowmeter cable. Download your wiring diagrams here. Wiring diagram for aftermarket tachometer a tachometer is gauge to measure mechanical speed in units of rpm revolutions per minute or rotations per minute. I pulled out my spreadsheet for rpms at speed in the different gears and saw that the engine should be turning 2000 rpm at 55 mph. The positive power pole is connected to the brown wire for the magnetic sensor negative power pole speed sensor blue wire from the sensor fourth position nothing connect. Cable dca analog cable diagram.

The linked images are printable but may print across more than 1 page in order to be legible. The cam and crk sensors are types of speed. If there is surface wave action then it may be advisable to use a stilling tube. Cable dcp power and remote start cable. The rpm device must be rotated by the display down then the correct wires according to the diagram on the back. On vehicle tachometer is measuring engine speed.

This video is dedicated to cam and crk sensor testing and operational parameter but from an electrical and wiring diagram interpretation point of view. Plug the connectors back into the pressure monitor. Cable dcrc custom rmp cable. If additional options need to be wired refer to building prints for proper wiring diagram. Cable dcr rpm cable. Please see the table below the negative.

Carefully push the wires into the electrical box and mount the pressure monitor. Dual function cable srpm and digital. I also ran two wires from the gear tooth sensor to this location and finished wiring the dsl 1. Three wire sensor in plc three wire sensor connection in plc. E1 0119 6 automation products roup inc. Pressure sensor wiring diagram duration.

Most models also have black white only.