Icm head pressure control wiring diagram icm defrost board wiring diagram as well as icm circuit board wiring diagram furthermore paragon 8141 20 defrost timer wiring diagram moreover wiring diagram icm defrost control furthermore icp heat pump wiring diagram also goodman b12260 08 wiring diagram along with goodman heat. For the safety and well being of our employees we have made scheduling adjustments and other accommodations to help comply with ny states social distancing policies pursuant to.

I Have A 91 Ford E350 With A 460 Gas Engine That Has No

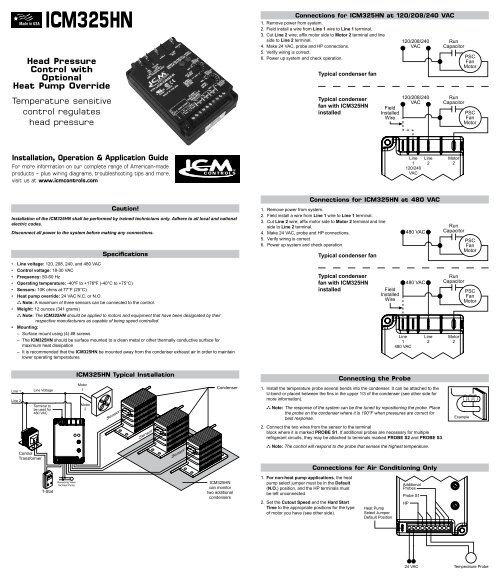

Icm head pressure control wiring diagram. Head pressure is regulated during low ambient conditions by varying the amount of airflow through the condenser. Hard start low temperature bypass isolated 24 vac supply rohs compliant lead free design controls up. It can be attached to the. Fan coil relay controls. Line voltage three phase monitor. Icm controls was granted an exemption from ny states 100 workforce reduction mandate and remains operational.

Control circuitry line voltage this terminal to be ac icm325hn typical wiring diagram for systems with a contactor icm sensor probe mounting recommendations high efficiency systems. The sensor probe should be mounted up several bends into the condenser upper 13 as shown at right to more closely monitor the condensing temperature. Install the temperature probe several bends into the condenser. Helps prevent evaporator freeze ups low pressure cut outs and liquid slugged compressors in low ambient conditions. Head pressure controls operate as temperature or pressure sensitive motor fan speed controls. Hard start low temperature cutoff high temperature bypass isolated 24 vac supply is built into the control.

This helps ensure sufficient pressure across the expansion valve preventing costly downtime andor loss of valuable perishable goods. 35 465 psig solid state 10 amp load carrying capability eliminates overshoots common to onoff and pressure switch controls helps prevent evaporator freeze ups low pressure cut outs and. Direct set up from line voltage. Supports up to two temperature or two pressure probes integral heat pump bypass circuitry allows electonic bypass of speed control dial temperature or pressure setpoint. Line voltage accessories. 45 l x 3 w x 2 h.

Line voltage single phase monitor. Click here to read the official exemption notice. Integral heat pump bypass circuitry allows electonic bypass of speed control eliminates overshoots common to onoff and pressure switch controls helps prevent evaporator freeze ups low pressure cut outs and liquid slugged compressors in low ambient conditions features.